Products

Products Cartoning machine

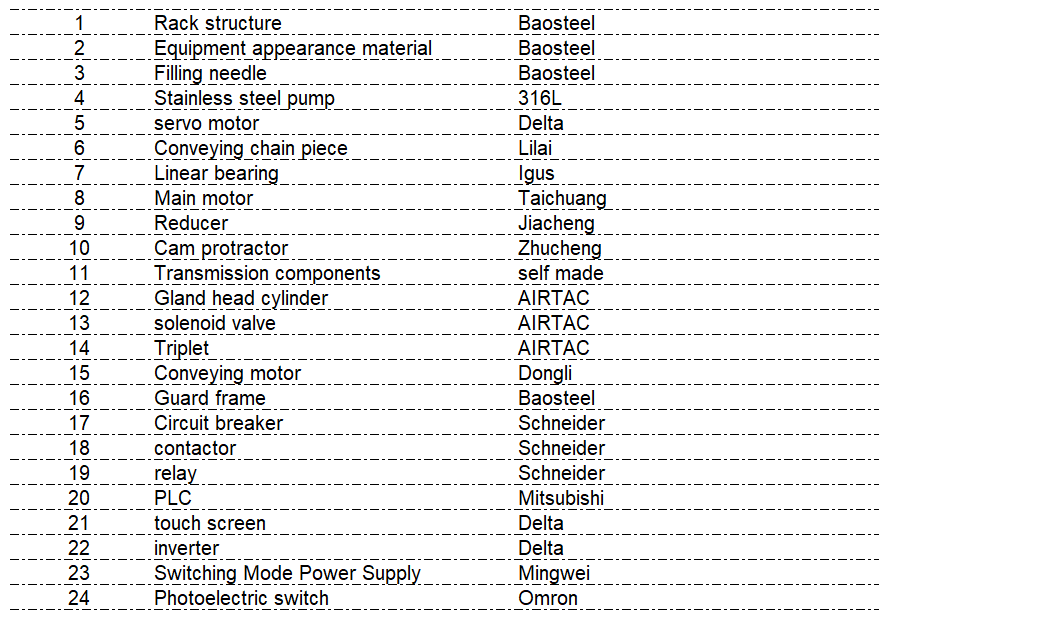

Cartoning machineDevice configuration

Technical characterstic

CM300 automatic cartoning machine

CM300 automatic cartoning machine is a full-automatic continuous high-speed cartoning machine. It is a high-performance product integrating machine, light, electricity and gas. It is suitable for automatic cartoning of aluminum plastic blister plate, bottle, hose, soft double aluminum and bagged articles, and can form a packaging production line with it.

Technical characteristics:

1. The relevant technologies of manual folding and conveying, carton forming and rear pushing mechanism meet European and American standards;

2. Automatic shutdown without carton, automatic shutdown without manual for many times;

3. Low compressed air and vacuum negative pressure shutdown alarm;

4. It is very easy to change the product specifications through the dial scale handwheel;

5. The main drive is equipped with overload protection device and adopts servo blanking system;

6. Sensors, relays, contactors and pneumatic components are all international well-known brands.

Performance characteristics

The machine has a wide range of applications, high efficiency, stable operation, and can be used for multiple purposes. It is suitable for the packaging of drugs, food and cosmetics. Its performance characteristics are as follows:

1. It can automatically complete the folding, cartoning, opening, section cartoning, batch number printing, sealing and other work of the manual.

2. The machine is controlled by PLC. Photoelectricity monitors the action of each part. In case of any abnormality during operation, it can automatically stop the machine to display the cause, so as to eliminate the fault in time.

3. The main drive motor and clutch brake are installed inside the rack, and the torque overload protector of the transmission system of each part is installed on the machine board, which can realize the disconnection of the main drive motor from each transmission part in case of overload, so as to ensure the safety of the whole machine.

4. The machine is equipped with a removal device. The instructions, drug plates and cartons are detected by sensors, and then output after batch number and box sealing. Any waste products (without drug version and instructions) found during the inspection shall be eliminated at the outlet to ensure that the product quality fully meets the requirements.

5. This machine is a continuous cartoning machine, which is more stable and faster than the traditional intermittent type.

6. The pushing mode of the machine is continuous and slow, so as to ensure that the product will not be damaged during the process of putting into the box.

7. The machine can be used alone or in conjunction with blister packaging machine and other equipment to form a complete production line

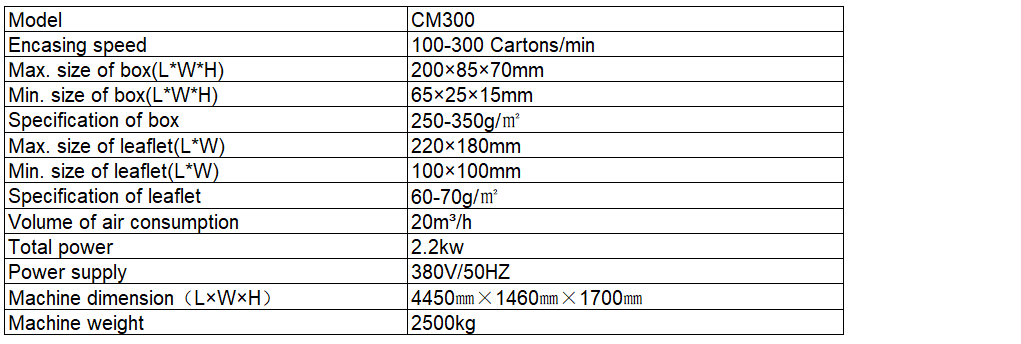

Technical parameters