Products

Products Cartoning machine

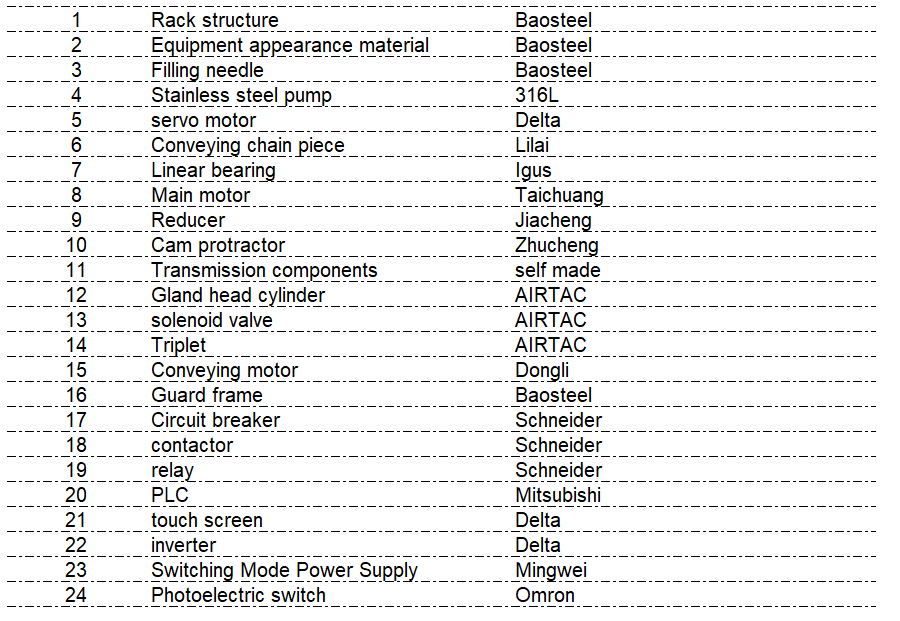

Cartoning machineDevice configuration

Technical characterstic

CM400 continuous automatic high-speed cartoning machine is a mechatronic product developed by our company based on years of production experience and advanced technology. It is composed of feeding - manual folding - drug box unfolding - drugs and instructions in the box - carton batch number printing - drug box sealing - finished product output and other components. It adopts the integrated automatic control of machinery, electricity, light and gas to realize the automatic production of drug packaging. Advanced detection means are used in all operation links, The unqualified products are automatically removed to ensure that the qualified rate of finished products is 100%, and the human error is controlled to a minimum, which effectively prevents the drug from being polluted in the packaging process, which leads to the decline of quality, ensures that the drug packaging production process fully meets the requirements of GMP, and greatly reduces the production cost and labor intensity.

The cm400 continuous automatic high-speed cartoning machine completely adopts the stable closed structure design to make the high-speed stable. The innovative compact design and ergonomic structure allow the operator to approach the equipment to the greatest extent and clean it. There is a special drawer bucket to collect the instructions and medicine plates generated by the test machine or failure. The whole body is wrapped in stainless steel, and the closed circuit and air circuit structure make the machine more humanized, The driving device is located at the rear of the machine and is fully open at the operator's side. It meets GMP requirements and is very easy to operate. The innovative compact design and ergonomic construction allow the operator to maximize access to the equipment and clean it. All operations are simple and easy.

Performance:

1. All equipment covers are made of high-quality 304 stainless steel covers and aluminum alloy tempered glass protective doors. The aluminum alloy tempered glass protective door can be equipped with a door control switch for protection. When the protective door is opened during normal production, the machine will automatically stop working to ensure the safety of operators.

2. The equipment adopts horizontal cartoning. The cartons are put into the rotating chain through the suction cup. The rotating chain operates continuously in the same direction. The cartons and drugs are packed and cartoned in a lying down manner.

3. The whole machine adopts continuous cartoning. The machine cartons in a stable operation state, and the mechanical operation noise and load are minimized.

4. The drugs are put into the box in a multi head and multi station way. Under the synchronous operation of the pusher, the drugs and the box, the pusher uses a linear cam mechanism to put the drugs into the box within a certain distance, and the drugs are put into the box in any non impact state.

5. The control system uses the man-machine interface touch screen to communicate with the machine, so as to adjust the program of each station and count the production status of the machine. Fault alarm display and other functions.

6. The program adopts PLC whole process automatic monitoring and photoelectric detection mechanism, which can automatically display, alarm and automatically remove the insufficient plate loading and carton paper jam, so as to ensure 100% qualified finished product output at the outlet. And the automatic counting is displayed on the screen.

7. The manual is clamped in the medicine plate bin and can be close to the box with the linear cam before loading, so as to ensure that the manual can be pushed 100% into the box.

8. The machine adopts a number of highly reliable mechanical overload automatic protection devices, so that the machine can protect itself from damage in case of emergencies during operation.

9. It is not necessary to replace parts during variety conversion, and it can be directly converted through the adjustment mechanism.

10. All parts in contact with drugs, including the secondary feeding hopper, are made of 304 stainless steel and non-toxic materials, meeting the requirements of "GMP".

11. Main functions: manual automatic folding (1-4 fold) conveying; Automatic material distribution and feeding; Cartons are automatically unfolded, instructions and materials are automatically boxed, batch numbers are synchronously printed (phase III), cartons are automatically sealed, and waste products are automatically removed.

12. Suitable for: Blister panel and others.

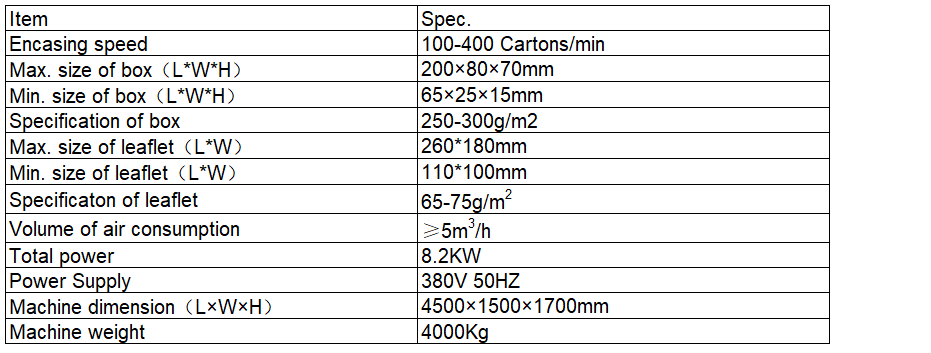

Technical parameters