Products

Products Sealer & Shrink Tunnel Machine

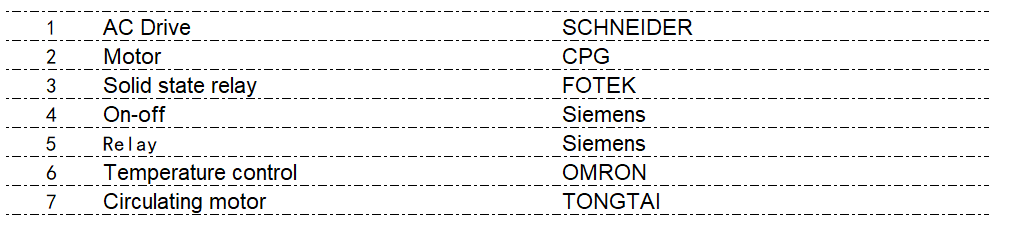

Sealer & Shrink Tunnel MachineConfiguration

Technical characterstic

●The machine is our company independently developed unmanned fully-auto side sealer which is widely used in mass packing production. Automatic feeding, conveying, putting into the bag, sealing and shrinking can complete in one time. It can be used for different height and width products with high working efficiency;

●Horizontal blade of sealing part uses vertical drive; side blade adopts the international advanced thermostatic side sealing knife. Sealing line is straight and strong which can guarantee the sealing in the middle of the product. It can keep continuously sealing and cutting to achieve perfect sealing effect;

●Temperature heating systems can be used for sealing various standard industrial films, such as POF shrink film. Only adjust the hand wheel to pack different sizes of the products that increase reliability and operate easier;

●Side blade sealing continuously makes the unlimited length of the product;

●The machine adopts the advanced PLC programmable controller, meanwhile it also has safety protection and alarm device. The sealing system can continue to make a smooth sealing action without replacement. The maintenance is very simple;

●The feeding length controlled by photo sensor and time relay which regulates film length precisely and makes the shrinking under control;

●In addition the installation of two groups of horizontal and vertical electric eyes are easy to switch choice for thin or small package that can easily complete sealing packaging operations;

●Auto waste film collection which is controlled by single motor will not make the film too loose or too tight. It is easy to remove the waste film;

●According to customer’s needs, vacuum feeding and gas charging can be added to make more beautiful shrinking;

●We also can equip the machine with in feed power line and outlet non-power storage table;

●It can be used for books, frame, aluminum, wooden products with single package or a combination of packaging. The machine is suitable for mass production of long materials.

●It uses advanced circulation technology and special manufacturing. The wind orientation can be adjusted and the shrink effect is good;

●The heating elements are stainless steel which has a long life span and high energy efficiency;

●The use of French Schneider inverter controls transmission speed which has the function of infinitive speed;

●Imported insulation curtain greatly reduces the heat loss;

●The shrink temperature, conveyor speed and air volume are adjustable;

●Visual window makes the shrinking process more clear;

●The conveyor uses new types of rollers covered with durable imported fiber tubes which have the functions of anti-high temperature, wear resistance, non-film damage, non-deforming and long terms using;

We can offer customized machine according to the size of your products!

We can replace the configuration according to your needs!

Warranty: 1 year. Within one year, we will replace the spare parts which are non-man made damage except the wearing parts.

But the customer should bear the express charge. After the guarantee, we will offer the spare parts at EXW price and we will

supply lifelong consulting services.

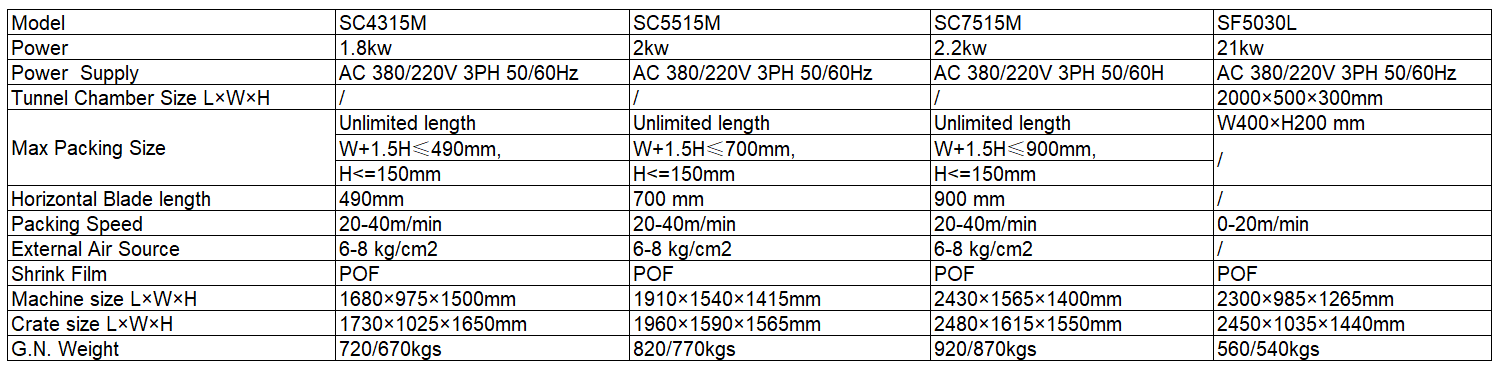

Technical parameters

Packaging Examples